The Semiconductor Water Crisis: Tech's Hidden Thirst

In the heart of every electronic device lies a critical component few consumers ever think about: semiconductors. These tiny technological marvels power our digital world, but their production comes with an environmental cost that's rarely discussed. The semiconductor industry consumes staggering amounts of water—billions of gallons annually—to create the chips in your smartphone, laptop, and countless other devices. As global chip demand surges amid supply chain disruptions, this massive water footprint is becoming increasingly problematic, especially in drought-prone regions where many manufacturing facilities operate.

The invisible resource behind your gadgets

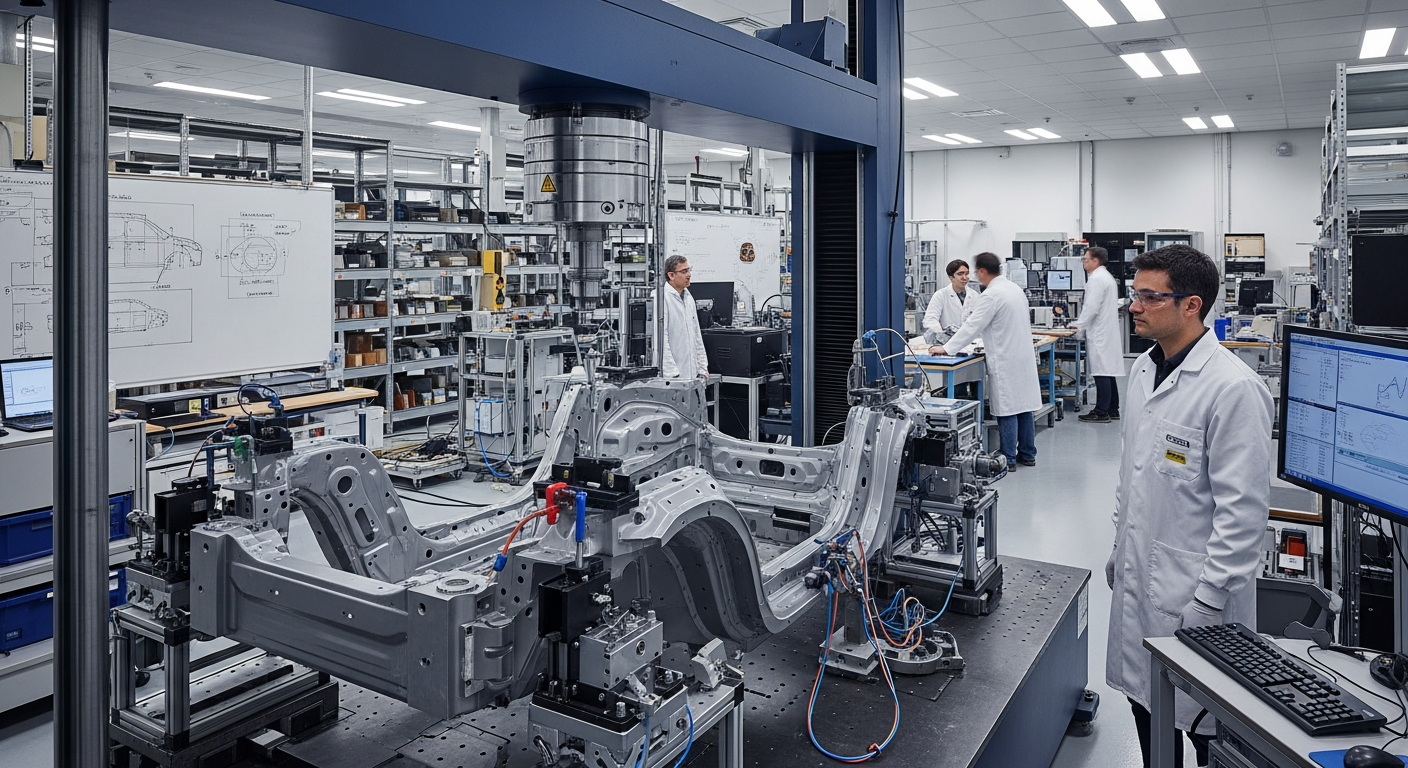

When you scroll through your smartphone or boot up your laptop, you’re unlikely to consider the astronomical amount of water that went into creating the chips powering your devices. A single semiconductor manufacturing facility—commonly called a fab—can use between 2-4 million gallons of ultra-pure water daily. That’s enough to fill several Olympic swimming pools, consumed by just one factory. The Taiwan Semiconductor Manufacturing Company (TSMC), which produces chips for Apple, AMD, and countless others, used approximately 156 million tons of water in 2020 alone—a figure that continues to rise as manufacturing processes become more complex.

The water used in semiconductor production isn’t just any water. It must be ultra-pure—a specialized grade that’s vastly cleaner than drinking water. Creating this ultra-pure water requires additional energy and filtration processes, adding another layer to the industry’s resource consumption. The irony is striking: while the devices themselves grow smaller and more efficient, their manufacturing process remains extraordinarily resource-intensive.

Geographic mismatch: chips and drought

Perhaps the most concerning aspect of the semiconductor water crisis is the geographic mismatch between fab locations and water availability. Taiwan, home to TSMC and responsible for over 60% of the world’s semiconductor manufacturing, has faced severe droughts in recent years. In 2021, the country experienced its worst drought in half a century, forcing semiconductor manufacturers to truck in water to maintain production. Similarly, Arizona—where Intel and TSMC are expanding operations—is amid a two-decade-long megadrought, with groundwater supplies rapidly depleting.

This geographic puzzle presents a growing challenge for the tech industry. Moving fabs to water-rich regions isn’t simple—semiconductor manufacturing requires specialized infrastructure, skilled labor, and stable geopolitical environments. These requirements often lead companies to established tech hubs, which frequently happen to be in water-stressed regions like California’s Silicon Valley, parts of Texas, or East Asia.

The economics of thirsty chips

The financial implications of semiconductor water usage extend beyond simple resource costs. As water scarcity increases, so does its price—a trend projected to continue as climate change intensifies drought conditions worldwide. Industry analysts estimate that water costs for semiconductor manufacturing could rise by 30-45% over the next decade in water-stressed regions.

For consumers, this translates to potential price increases across the electronic device spectrum. The current global chip shortage has already demonstrated how supply chain disruptions can drive up costs—a water-related production slowdown could have similar effects. Mid-range smartphones that currently sell for $400-600 could see price hikes of $30-50 if water costs are passed down the supply chain. High-performance computing chips, which require even more intensive manufacturing processes, could experience more significant price impacts.

Beyond direct costs, the industry faces increasing regulatory scrutiny. Several governments in water-stressed regions are implementing stricter water usage regulations, forcing companies to invest in water recycling and conservation technologies—expenses that ultimately influence product pricing.

Innovation in conservation

Facing these challenges, the semiconductor industry is beginning to innovate in water conservation. Companies like Intel and Samsung have made ambitious commitments to reduce water usage and increase recycling rates. Intel aims to achieve net positive water use by 2030, while TSMC has pledged to increase water recycling to 90% at its facilities.

Advanced water recycling systems now allow fabs to reuse up to 85% of their water, a significant improvement from the 40-50% that was standard a decade ago. Technologies like reverse osmosis and electrodeionization have become more efficient, reducing the energy required to purify and recycle water. Some facilities have also implemented rainwater harvesting systems and on-site water treatment that allows municipal wastewater to be upgraded to manufacturing standards.

These innovations carry substantial upfront costs—installing comprehensive water recycling systems can add hundreds of millions to a fab’s construction budget. However, the long-term savings and security they provide are increasingly viewed as essential investments rather than optional extras.

Community tensions and corporate responsibility

As semiconductor manufacturing expands into new regions, community tensions around water usage have emerged. In Arizona, public concerns have grown about how TSMC’s planned facilities will impact local water supplies. Similar debates are occurring in Texas, where Samsung is expanding operations, and in parts of Europe targeted for new fab development.

These tensions have pushed companies toward more transparent water stewardship policies. Leading chip manufacturers now regularly publish water usage data and conservation plans, a practice that was uncommon just five years ago. Many firms are also engaging in community water projects, funding infrastructure improvements that benefit both their operations and local residents.

The complexity of this issue highlights the delicate balance the tech industry must maintain—continuing to meet global demand for increasingly powerful devices while addressing the environmental impacts of their production. As consumers become more environmentally conscious, water footprint may join energy efficiency and material sourcing as factors influencing purchasing decisions.

The sustainable semiconductor future

The semiconductor water crisis represents a perfect storm of increasing technological demand, climate change, and geographic constraints. Yet it also presents an opportunity for meaningful innovation. The industry that transformed human communication and computing may need to apply similar revolutionary thinking to its relationship with water.

While current conservation efforts are meaningful, truly sustainable semiconductor manufacturing will likely require fundamental process redesigns. Research into dry etching techniques, alternative cooling systems, and new cleaning methods could dramatically reduce water requirements. These innovations, though still emerging, point toward a future where powerful chips don’t necessarily require powerful thirst.

For consumers, understanding the water behind their devices adds another dimension to responsible tech consumption. As this hidden aspect of electronics manufacturing becomes more visible, it may join considerations like repairability, energy efficiency, and ethical material sourcing in shaping our relationship with technology.