The Hidden Science of Automotive Paint Protection Films

Invisible guardianship for your vehicle's exterior has evolved from simple plastic wrap to sophisticated engineered solutions. Automotive paint protection films (PPFs) represent one of the most significant advancements in vehicle appearance preservation technology of the past decade. These virtually invisible shields stand as the first line of defense against road debris, chemical contaminants, and environmental hazards that threaten your vehicle's factory finish. While most drivers recognize the value of maintaining their car's appearance, few understand the complex materials science and engineering principles that make modern protection films so effective. The technology behind these defensive layers combines chemistry, physics, and automotive engineering in ways that fundamentally change how we preserve vehicle aesthetics.

The Molecular Architecture of Modern Protection Films

Today’s automotive protection films bear little resemblance to their primitive predecessors used in military applications decades ago. Modern PPF utilizes multi-layered thermoplastic urethane constructions, typically consisting of four distinct functional layers. The adhesive layer creates a molecular bond with your vehicle’s clear coat without damaging it. Above this sits the polyurethane core layer, engineered with elastomeric polymers that allow the film to stretch during installation and recover from impacts. The third layer contains specialized compounds that provide self-healing properties through thermal activation. Finally, the topmost layer incorporates hydrophobic nanotechnology and UV stabilizers that prevent yellowing and degradation.

The scientific breakthrough in modern films came with the development of self-healing elastomers. These remarkable materials contain polymers with temporary hydrogen bonding that can reconnect after being broken. When minor scratches occur, these molecular bonds reconnect when exposed to heat, effectively “healing” the surface imperfection. This process can occur naturally on hot days or can be accelerated with warm water or heat guns. Some premium films now incorporate nanomaterials that enhance this self-healing capability while adding additional properties like increased hydrophobicity and greater optical clarity.

Installation Techniques: Where Art Meets Science

Installing paint protection film requires a methodical approach combining technical knowledge with skilled craftsmanship. Professional installers first prepare surfaces meticulously, removing any contaminants that could affect adhesion. This process involves clay bar treatments, specialized cleaning solutions, and sometimes paint correction procedures to ensure the film bonds perfectly with the underlying surface. The vehicle’s dimensions must be precisely measured, and the film cut using computer-assisted design programs that account for the complex curves and contours of modern automotive bodywork.

The application itself involves a technique called wet installation, where specially formulated slipping solutions allow the installer to position the film accurately before adhesion occurs. This solution typically contains surfactants that temporarily prevent the adhesive from bonding, providing a crucial installation window. Temperature and humidity control within the installation environment is critical – too cold, and the film becomes rigid and difficult to manipulate; too humid, and water can become trapped beneath the surface. Master installers develop a tactile sensitivity that allows them to feel and eliminate microscopic air pockets that would otherwise lead to bubbles or adhesion failures.

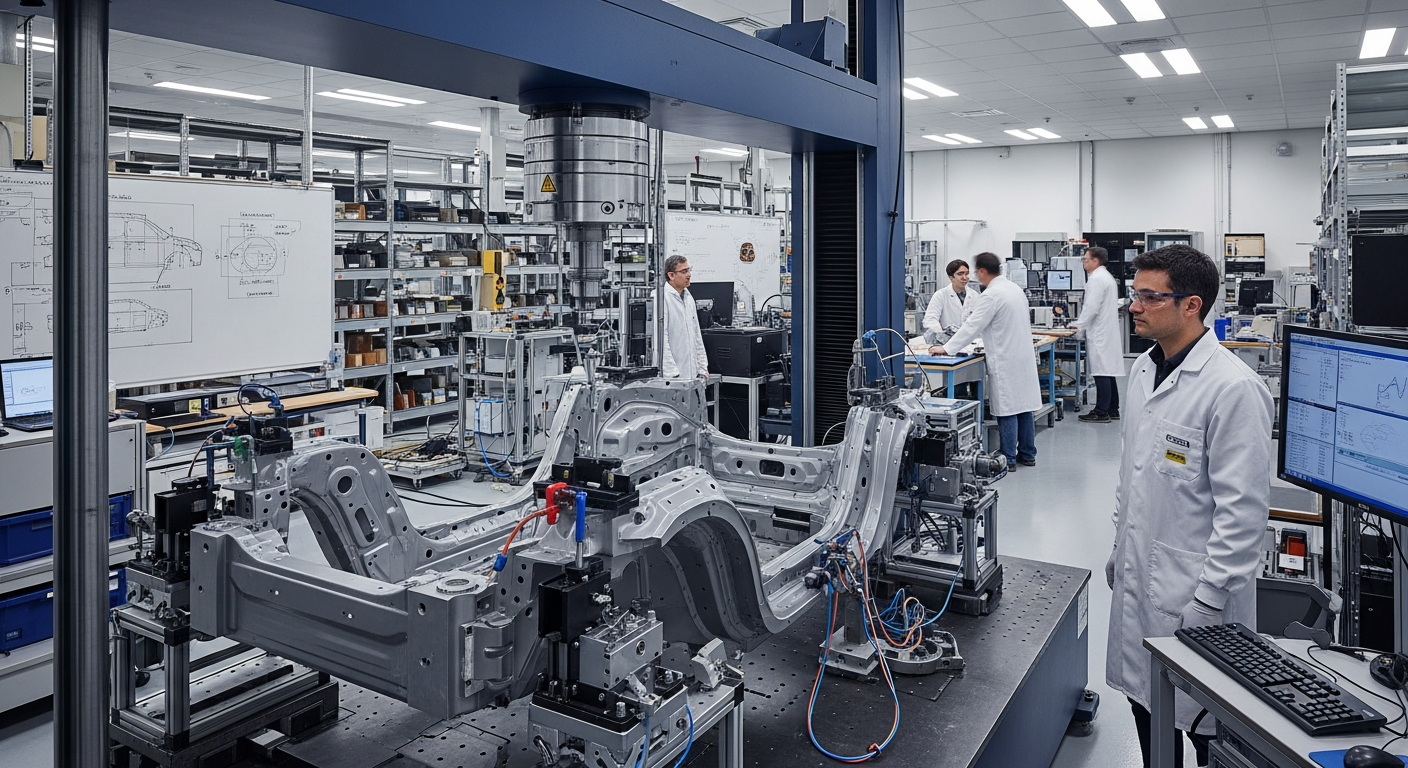

Performance Testing and Industry Standards

The automotive protection film industry has developed rigorous testing protocols to evaluate product performance across multiple dimensions. Weathering resistance tests expose materials to accelerated aging conditions, including continuous UV bombardment, extreme temperature cycling, and simulated acid rain exposure. These tests, conducted in specialized environmental chambers, can compress years of environmental exposure into weeks. Impact resistance evaluation involves propelling standardized projectiles at controlled velocities to measure the film’s ability to absorb energy without allowing damage to reach the underlying paint.

Chemical resistance testing exposes protection films to automotive fluids, bird droppings, tree sap, and insect residue – all notorious for damaging automotive finishes. The most advanced films demonstrate remarkable resistance to these substances while maintaining optical clarity. Optical testing measures haze, transmittance, and reflection values to ensure the film remains virtually invisible once applied. These standardized tests allow manufacturers to make verifiable claims about their products’ protective capabilities and help consumers make informed decisions when selecting protection for their vehicles.

Economic and Environmental Considerations

The financial equation of paint protection film application extends beyond the initial installation cost. Modern vehicles with complex paint systems, such as tri-coat pearlescent finishes or matte completions, can require thousands of dollars in repair costs for even minor damage. In this context, protection films represent a preventative investment that maintains resale value by preserving factory finish integrity. Insurance companies have begun recognizing this value proposition, with some premium auto policies now offering coverage for professional PPF installation as part of comprehensive protection packages.

From an environmental perspective, paint protection films contribute to sustainability by extending the usable life of automotive finishes, reducing the need for resource-intensive repainting procedures. Traditional automotive paint processes involve volatile organic compounds and generate significant waste. By preventing damage that would otherwise necessitate repainting, protection films reduce the environmental footprint of vehicle maintenance. Additionally, newer film technologies are being developed with improved biodegradability at end-of-life while maintaining performance standards during their useful service period. Some manufacturers have implemented recycling programs for removed film, further reducing environmental impact.

Future Developments: Beyond Passive Protection

The next generation of automotive protection films promises to transcend passive defense by incorporating active technologies. Research laboratories are developing films with embedded sensors that can detect and report impacts, providing valuable data for both vehicle owners and insurance companies. These smart films could potentially link to vehicle telematics systems, documenting exactly when and where damage occurred. Other innovations include photocatalytic coatings that actively break down organic contaminants when exposed to sunlight, essentially creating self-cleaning surfaces.

Perhaps most exciting are developments in self-repairing technologies beyond current thermal healing capabilities. Biomimetic approaches inspired by natural healing processes are yielding films containing microcapsules of repair agents that activate upon impact. When damaged, these capsules rupture and release compounds that solidify and restore the protective barrier. Another approach involves incorporating conductive elements within the film that can generate heat on demand through low-voltage electrical current, activating healing properties without external heat sources. As these technologies mature, we may see protection films transition from passive barriers to active components of the vehicle’s protective ecosystem, continuously monitoring and maintaining exterior surfaces with minimal human intervention.