Strategic Waste Reduction Through Industrial Byproduct Synergies

Transforming manufacturing waste streams into valuable resources represents one of the most underutilized business opportunities in modern industry. Companies across multiple sectors are discovering that materials once destined for disposal can become valuable inputs for other processes, creating new revenue streams while simultaneously reducing environmental impact and operational costs. This approach moves beyond simple sustainability initiatives into strategic business development, where waste reduction becomes a competitive advantage rather than merely a compliance requirement. The growing market for repurposed industrial byproducts demonstrates a fundamental shift in how forward-thinking organizations view their production ecosystems.

The Hidden Value in Manufacturing Waste

Manufacturing operations traditionally generate significant waste streams as an inevitable consequence of production processes. These byproducts range from excess materials and trimmings to chemical residues and thermal energy. Historically, companies focused primarily on disposal methods that met regulatory requirements at minimal cost. This approach overlooked the intrinsic value these materials still possessed—a value that could be realized through innovative thinking and strategic partnerships. Research from the Ellen MacArthur Foundation indicates that over $1 trillion in material value is lost annually through conventional waste disposal practices. This represents not just environmental damage but substantial unrealized economic opportunity.

The concept of industrial byproduct synergy fundamentally reframes the relationship between waste and value. Rather than viewing production residuals as a liability requiring management, companies are increasingly recognizing these materials as potential assets requiring optimization. This perspective shift transforms waste management from a cost center to a potential profit center. Multinational consumer goods manufacturer Unilever, for example, now generates over $200 million annually from byproducts that were previously treated as waste—transforming what was once an expense into a significant revenue source that simultaneously enhances sustainability metrics.

Cross-Industry Collaboration Models

The most successful byproduct synergy programs typically involve collaboration across different industrial sectors, where one company’s waste becomes another’s raw material. These symbiotic relationships create mutual value and strengthen business networks. Chemical manufacturing byproducts can become inputs for construction materials; food processing waste can support agricultural amendments; excess heat from industrial processes can provide energy for neighboring facilities or communities.

The Kalundborg Symbiosis in Denmark represents the gold standard for such collaborative ecosystems. Beginning in the 1970s, this network has expanded to include nine public and private companies that exchange 20 different resource streams, including steam, gas, water, and various material byproducts. This industrial ecosystem has developed organically over decades, demonstrating both immediate and long-term benefits for participants. Companies in the network report 15-20% reductions in operating costs and similar reductions in carbon emissions through these strategic partnerships.

More recently, digital platforms have emerged to facilitate these exchanges beyond geographical proximity. Online marketplaces like the Materials Marketplace allow companies to list waste streams and discover potential matches, expanding the potential for byproduct synergy beyond industrial parks or co-located facilities. These platforms effectively create virtual industrial ecosystems that can operate across regional or even national boundaries.

Financial Benefits Beyond Cost Avoidance

While waste reduction initiatives have traditionally been justified through cost avoidance—reducing disposal fees and regulatory compliance expenses—byproduct synergies offer much broader financial benefits. These include new revenue generation, reduced raw material costs, enhanced brand value, and improved stakeholder relations.

Companies implementing comprehensive byproduct management strategies report average returns on investment exceeding 200%. These returns come through multiple channels: direct sales of byproducts, reduced waste management costs, decreased raw material purchasing, and in some cases, tax incentives or regulatory credits. Interface Inc., a leading carpet manufacturer, generates over $10 million annually through their ReEntry program, which recovers and repurposes materials from old carpeting. This program simultaneously reduces virgin material needs and creates a dedicated return channel that strengthens customer relationships.

For industries with thin profit margins, these gains can significantly impact overall profitability. A food processor operating at a 5% profit margin that reduces waste disposal costs by just 1% of revenue effectively increases profitability by 20%. When combined with revenue from byproduct sales, these improvements can transform marginal operations into highly profitable ones without requiring major capital investment or process redesign.

Implementation Strategies for Successful Programs

Developing effective byproduct synergy programs requires systematic analysis and implementation strategies. Companies seeing the greatest success typically follow a structured approach that begins with comprehensive waste stream audit and characterization.

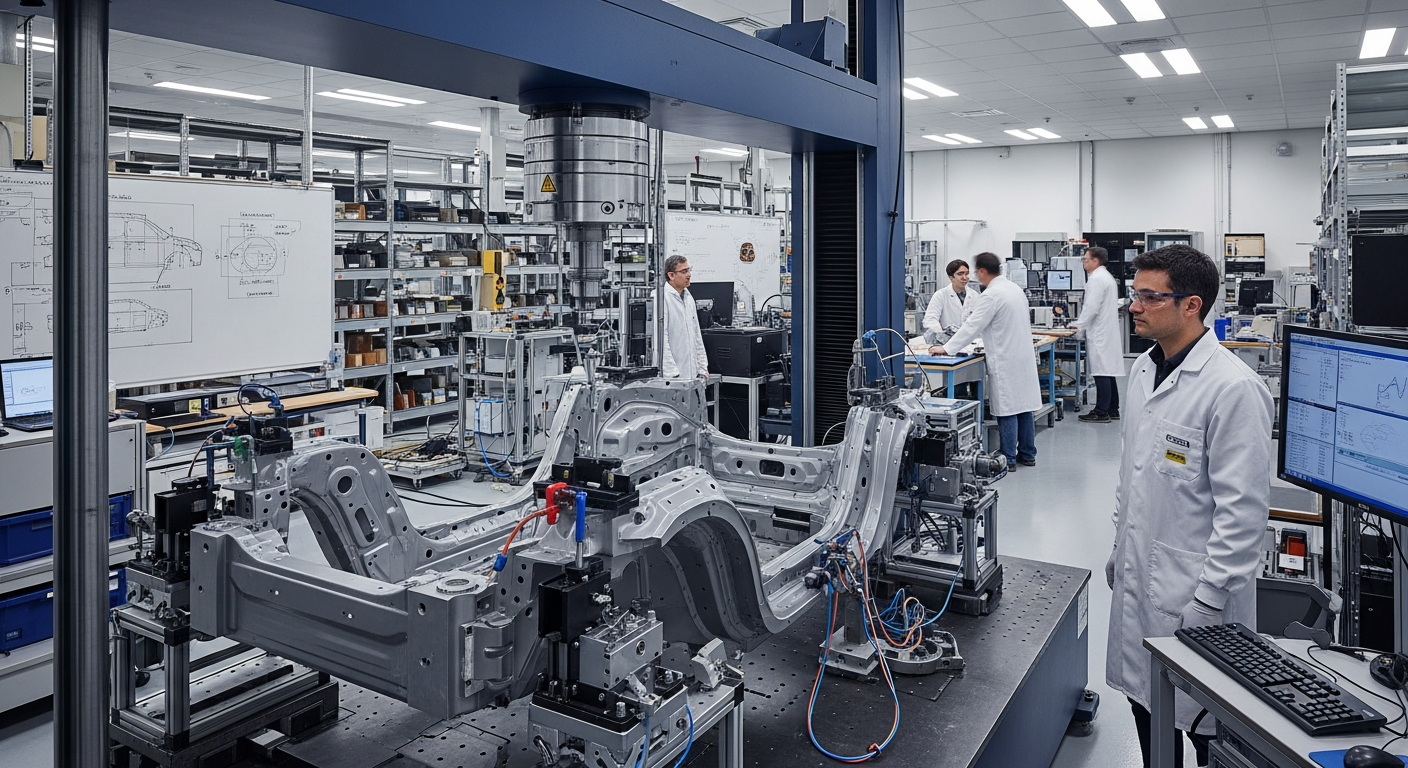

The first step involves thorough inventory and analysis of all waste streams, including detailed physical and chemical characterization. This provides essential data for identifying potential applications and markets. Advanced analytics platforms can help quantify volumes, composition variability, and potential value of each stream. This baseline assessment should capture seasonal variations and production anomalies to ensure accurate understanding of available materials.

Next comes market research to identify potential synergy partners or applications. This often requires creative thinking beyond traditional industry boundaries. Technical feasibility studies must validate that the byproduct meets quality and consistency requirements for any identified application. These studies should address questions of transport, storage stability, processing requirements, and regulatory compliance.

Finally, successful implementation requires relationship development with potential partners or customers, often supported by pilot programs that demonstrate value before scaling. These relationships benefit from formalized agreements addressing specifications, volumes, pricing structures, and contingency plans. Companies that take a collaborative approach, recognizing mutual benefit rather than pursuing transactional relationships, typically achieve more sustainable and profitable outcomes.

Overcoming Common Implementation Challenges

Despite clear benefits, companies implementing byproduct synergy initiatives face several common challenges. Understanding these obstacles and developing mitigation strategies significantly improves success rates. The most frequently encountered barriers include inconsistent material quality, regulatory constraints, organizational resistance, and complex logistics.

Material consistency represents a primary concern for potential byproduct users. Manufacturing processes designed for primary products may produce variable waste streams unsuitable for applications requiring strict specifications. Addressing this challenge often requires additional processing, quality control systems, or identification of applications tolerant to variation. Some companies have successfully implemented real-time monitoring and sorting technologies to maintain consistent quality or divert non-compliant materials to alternative uses.

Regulatory frameworks designed for traditional waste management can unintentionally impede byproduct utilization. Materials classified as waste face transport restrictions, permitting requirements, and liability concerns that complicate repurposing efforts. Progressive companies engage proactively with regulators, demonstrating safety and environmental benefits to establish appropriate compliance pathways. Industry associations increasingly advocate for regulatory modernization that distinguishes between hazardous waste and valuable byproducts.

Strategic Implementation Guidelines

-

Conduct detailed material flow analysis before implementing any program, identifying all inputs, outputs, and potential synergy opportunities

-

Develop internal expertise in byproduct characterization and valorization, creating dedicated roles responsible for identifying new opportunities

-

Start with high-volume or high-value waste streams to demonstrate concept viability before addressing more challenging materials

-

Create clear quality specifications and sampling protocols to ensure consistency for byproduct recipients

-

Establish contingency plans addressing production variations, market fluctuations, and potential partnership disruptions

-

Consider geographic proximity when identifying partners to minimize transportation costs and associated emissions

-

Document all financial and environmental benefits to build organizational support for program expansion

The transition from viewing manufacturing residuals as waste to recognizing them as valuable byproducts represents more than a semantic shift—it fundamentally changes operational approaches and opens new business opportunities. Companies successfully implementing byproduct synergy programs achieve simultaneous financial, environmental, and social benefits, demonstrating that economic and ecological goals can be complementary rather than competing. As resource constraints intensify and regulatory pressures increase, these collaborative approaches to material management will likely become standard practice across industrial sectors, representing a core component of business strategy rather than a peripheral sustainability initiative.