Strategic Capital Allocation for Manufacturing Excellence

The intricate dance of capital allocation within manufacturing enterprises represents one of the most consequential decisions executives face in today's volatile economic landscape. When manufacturing firms direct investments with precision, they can dramatically enhance operational capabilities, strengthen market position, and deliver superior shareholder returns. However, many organizations struggle with this fundamental aspect of business strategy, often relying on outdated frameworks that fail to account for emerging market dynamics. Capital allocation decisions require not just financial acumen but a deep understanding of technological trajectories, competitive forces, and long-term strategic imperatives. These choices ultimately determine which manufacturing organizations will thrive and which will fade into obsolescence as industry paradigms continue to evolve.

Understanding the Capital Allocation Matrix

Capital allocation in manufacturing encompasses every decision about where to invest a company’s financial resources - from equipment upgrades and facility expansions to research initiatives and strategic acquisitions. Effective allocation begins with a comprehensive assessment of the current manufacturing asset base, identifying performance gaps, obsolescence risks, and capacity constraints. Leading manufacturers employ sophisticated portfolio analysis techniques to categorize investments based on their strategic importance and financial return profiles. This approach enables executives to differentiate between investments that maintain operational integrity, those that drive incremental improvements, and those that potentially transform the manufacturing footprint. The most successful practitioners develop clear investment thresholds and decision criteria tailored to each category, ensuring that capital flows to initiatives with the greatest potential impact.

Balancing Short-term Performance and Long-term Capability Building

Manufacturing executives constantly navigate the tension between delivering immediate financial results and investing in capabilities that will secure competitive advantage in the future. Short-term pressures often lead to postponement of critical infrastructure investments, creating an “investment deficit” that compounds over time. Progressive manufacturers are addressing this challenge by implementing dual-horizon capital planning processes. These frameworks explicitly allocate a predetermined percentage of available capital to long-term strategic initiatives, protecting these investments from quarterly performance pressures. Some organizations have established separate governance mechanisms for evaluating short-term and long-term investments, with different metrics and decision authorities for each category. This structural separation helps prevent the systematic bias toward immediate returns that plagues many capital allocation systems and enables manufacturing firms to maintain a healthy pipeline of transformational projects.

Incorporating Operational Flexibility into Investment Decisions

Traditional capital allocation models often undervalue operational flexibility - the ability to rapidly adjust manufacturing capabilities in response to changing market conditions. In an era of increasing volatility, the premium on flexibility has grown substantially. Forward-thinking manufacturers now quantify and incorporate this flexibility premium into their investment analyses. For example, modular production systems that can be reconfigured to accommodate different product variants may appear costly in conventional ROI calculations but deliver superior value when market shifts are frequent. Similarly, investments in manufacturing technologies that reduce minimum efficient scale can create options to serve emerging market segments that would otherwise be inaccessible. By adopting real options valuation techniques, manufacturing leaders can properly account for the strategic value of flexibility when making capital commitments.

Strategic Manufacturing Footprint Optimization

Capital allocation decisions shape the geographic distribution and technological capability of a manufacturer’s production network. Footprint optimization represents one of the highest-leverage applications of strategic capital allocation. Leading companies approach footprint decisions through a multidimensional lens, simultaneously considering production costs, market proximity, talent availability, supply chain resilience, and tax implications. The most sophisticated practitioners develop comprehensive scenario models that simulate how different footprint configurations would perform under various future states of the world. These analyses often reveal counterintuitive insights - for example, that consolidating production in a single high-efficiency facility may increase overall system risk despite lower unit costs. Manufacturing organizations that excel at footprint optimization typically establish dedicated teams with cross-functional expertise to continuously refine their production networks rather than addressing these questions episodically.

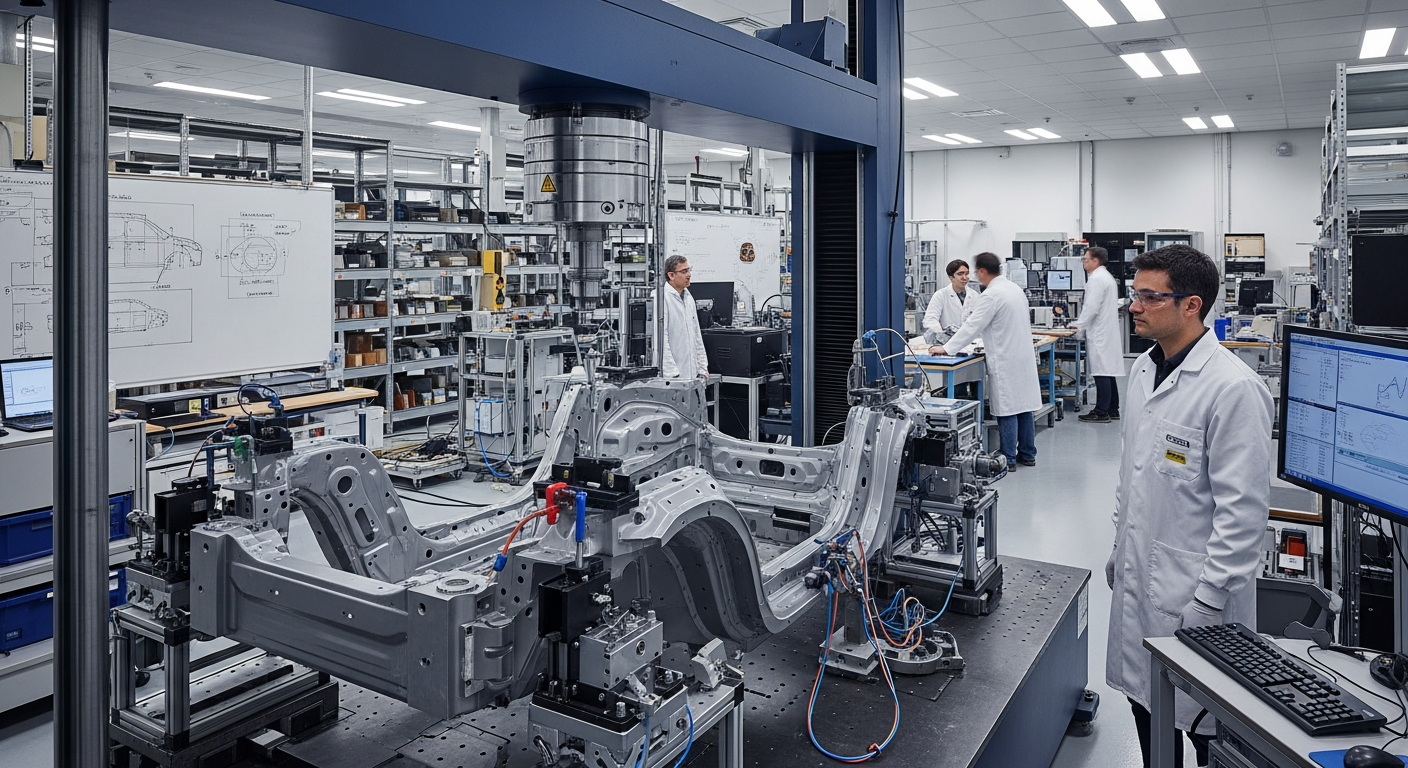

Technology Investment Prioritization

The proliferation of advanced manufacturing technologies presents executives with an unprecedented array of investment options. From advanced robotics and additive manufacturing to industrial sensing systems and manufacturing execution software, the landscape of potential investments has grown exponentially more complex. Leading manufacturers have developed structured frameworks for technology prioritization that extend beyond traditional financial metrics. These frameworks typically evaluate technologies along multiple dimensions, including operational impact, implementation feasibility, competitive differentiation potential, and strategic fit. High-performing organizations also consider how technologies might combine synergistically to unlock capabilities greater than the sum of individual components. This systems perspective helps manufacturers avoid the common pitfall of pursuing disconnected technology initiatives that deliver limited value in isolation.

Strategic Capital Allocation: Practical Implementation Guide

-

Establish a formal capital review board with diverse functional representation to counter departmental biases

-

Implement a tiered approval process with different evaluation criteria for maintenance, improvement, and transformational investments

-

Develop explicit linkages between strategic plans and capital allocation priorities, reviewing alignment quarterly

-

Create a dedicated funding pool for experimental manufacturing initiatives with accelerated approval processes

-

Require post-implementation reviews for major investments, comparing actual results against projections

-

Incorporate scenario planning into capital decisions, testing investment resilience across multiple potential futures

-

Consider “capital light” alternatives like manufacturing partnerships before committing to owned assets

-

Evaluate investments in manufacturing capabilities as a portfolio rather than as isolated decisions

-

Maintain a rolling five-year capital plan that identifies major investment needs beyond the annual budget cycle

-

Track the ratio of strategic to tactical spending, establishing targets for each category

Cultivating Capital Discipline for Manufacturing Success

Strategic capital allocation represents perhaps the clearest expression of a manufacturer’s actual priorities and strategic direction. While many organizations articulate ambitious visions in their strategic plans, their capital allocation patterns often reveal more incremental ambitions. By implementing rigorous processes that balance performance imperatives across multiple time horizons, manufacturing leaders can ensure that capital flows to initiatives with the greatest potential to create sustainable competitive advantage. The organizations that master this discipline will be positioned to outperform competitors, not just in immediate financial metrics, but in building the operational capabilities that secure their relevance and profitability for decades to come.