Quantum Manufacturing: Redefining Production Beyond Classical Constraints

Quantum technologies are quietly transforming industrial manufacturing capabilities, creating unprecedented opportunities for precision, efficiency, and innovation. As manufacturing companies face increasing pressure to optimize operations while reducing environmental impact, quantum-based solutions offer a paradigm shift in how products are designed, tested, and produced. This emerging field combines quantum physics principles with industrial applications to solve problems previously considered insurmountable.

Quantum Manufacturing Fundamentals

Quantum manufacturing represents the integration of quantum mechanics principles into industrial production processes. Unlike traditional manufacturing that operates under classical physics constraints, quantum manufacturing harnesses quantum phenomena such as superposition, entanglement, and quantum coherence to enable unprecedented capabilities. These quantum properties allow for simultaneous processing of multiple states, creating exponential increases in computational power for solving complex manufacturing challenges. The field emerged from theoretical physics laboratories in the early 2000s but has rapidly evolved into practical applications across diverse industries including pharmaceuticals, materials science, and precision engineering. Today’s quantum manufacturing encompasses specialized sensing equipment, quantum-enhanced optimization algorithms, and quantum simulation techniques that collectively transform how products are conceived, designed, and produced.

Material Innovation Through Quantum Simulation

Quantum simulation is dramatically accelerating materials discovery and development, a process previously constrained by classical computing limitations. Traditional material development follows a trial-and-error approach, requiring years of laboratory testing before implementation. Quantum simulation changes this paradigm by enabling accurate modeling of molecular and atomic interactions, allowing scientists to predict material properties with unprecedented precision. For example, automobile manufacturers are using quantum simulation to develop lighter, stronger alloys that maintain structural integrity while reducing vehicle weight and improving fuel efficiency. Similarly, aerospace companies employ quantum simulation to design high-performance materials that withstand extreme conditions. The practical impact extends beyond performance enhancements to sustainability, as quantum-simulated catalysts are pioneering more efficient chemical processes that consume less energy and generate fewer waste products, addressing both economic and environmental concerns simultaneously.

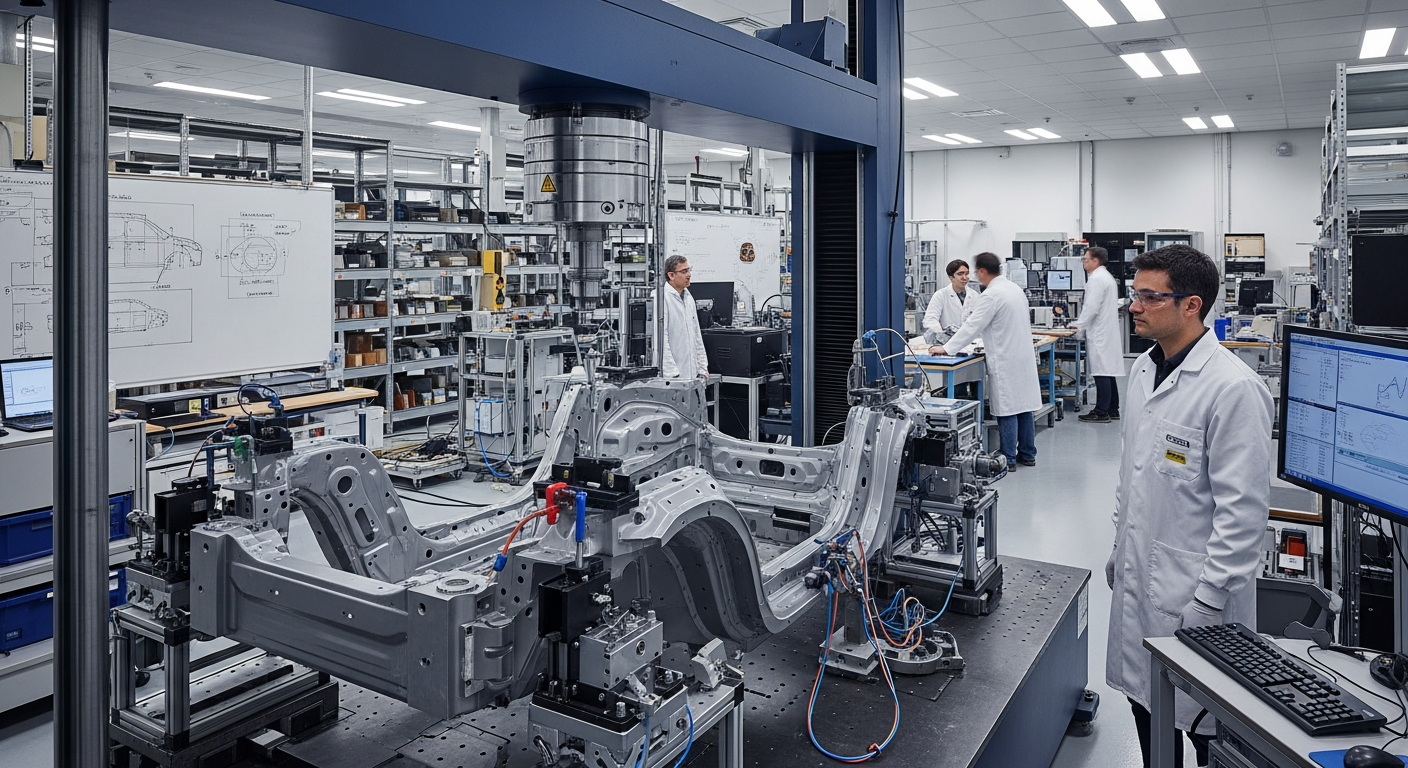

Quantum-Enhanced Precision Engineering

Precision engineering has reached new frontiers through quantum sensing technologies. Quantum sensors leverage principles like quantum entanglement to detect minute variations in electromagnetic fields, gravity, and other physical properties with sensitivity levels unachievable by classical instruments. In manufacturing settings, these capabilities translate to nanometer-level precision in production processes. Semiconductor fabrication facilities now employ quantum-enhanced lithography techniques to create circuit patterns at scales previously considered impossible. Similarly, medical device manufacturers utilize quantum sensors to ensure micron-level accuracy in implantable devices. A striking example comes from a European precision optics manufacturer that reduced defect rates by 87% after implementing quantum sensing technology in their quality control systems. The economic implications are substantial, with production yields improving while material waste decreases, creating a competitive advantage through superior product consistency and reduced manufacturing costs.

Optimization of Complex Manufacturing Systems

Manufacturing optimization presents extraordinary computational challenges that quantum computing is uniquely positioned to address. Modern manufacturing facilities contain thousands of interdependent variables affecting production flow, resource allocation, and scheduling—creating optimization problems beyond classical computing capabilities. Quantum algorithms excel at rapidly exploring vast solution spaces to identify optimal configurations. A North American automotive manufacturer recently deployed quantum optimization techniques to reconfigure its assembly line scheduling, resulting in a 23% throughput improvement without additional capital investment. Similarly, a pharmaceutical company used quantum-enhanced modeling to optimize batch processing sequences, reducing production time by 31% while maintaining quality standards. These applications represent early implementations of quantum advantage in industrial settings, where the ability to process multiple solution pathways simultaneously translates directly to operational efficiency improvements that classical approaches cannot match.

Quantum Cryptography for Industrial Security

As manufacturing becomes increasingly digitized, securing intellectual property and operational technology has become paramount. Quantum cryptography offers unprecedented security advantages through quantum key distribution (QKD) systems that detect any attempted interception of communication. Unlike classical encryption methods vulnerable to future quantum computing attacks, quantum cryptography provides theoretically unbreakable security based on fundamental physics principles rather than mathematical complexity. Several multinational manufacturing corporations have begun implementing quantum-secure communication channels to protect proprietary design data and manufacturing process specifications. A Japanese precision engineering firm recently established a quantum-secured network connecting its R&D facilities with production plants across three countries, ensuring that proprietary manufacturing techniques remain protected. As industrial espionage threatens competitive advantages, quantum security implementations represent prudent investments in long-term intellectual property protection.

Strategic Implementation Approaches for Quantum Manufacturing

-

Conduct a quantum readiness assessment to identify specific manufacturing challenges suited for quantum solutions

-

Begin with hybrid classical-quantum approaches that leverage existing infrastructure while introducing quantum components

-

Develop partnerships with quantum technology vendors and academic research institutions to accelerate implementation

-

Focus initial quantum applications on high-value problems where even incremental improvements deliver significant ROI

-

Invest in workforce development programs to build internal quantum literacy across engineering and operations teams

-

Establish a quantum technology roadmap aligned with your manufacturing strategy and capability development goals

The integration of quantum technologies into manufacturing represents not merely an incremental improvement but a fundamental reconceptualization of production possibilities. As quantum computing hardware continues maturing and quantum algorithms become more sophisticated, manufacturers who establish early expertise will gain substantial competitive advantages. While full-scale quantum manufacturing may still be evolving, forward-thinking industrial leaders are already implementing hybrid approaches that combine classical and quantum methods to address their most challenging operational problems. The journey toward quantum manufacturing requires vision, technical expertise, and strategic patience—but those who navigate this transition successfully will define manufacturing excellence in the coming decades.