Liquid-Cooled Charging Cables: The Next Frontier in Ultra-Fast EV Charging

The world of electric vehicle charging is undergoing a quiet revolution that few everyday drivers have noticed. Beyond the headlines about charging station networks and battery technologies lies an innovation that could dramatically change how quickly we power our electric vehicles: liquid-cooled charging cables. These specialized conductors represent a significant breakthrough in addressing one of the most persistent challenges in electric mobility – charging speed. By implementing advanced cooling systems directly within charging cables, engineers have created a pathway to deliver unprecedented power levels safely, potentially reducing charging times from hours to mere minutes.

The Physics Challenge Behind Fast Charging

Electric vehicle charging faces a fundamental physical constraint that has limited progress for years. When electricity flows through any conductor, it generates heat through resistance. As charging speeds increase and more current passes through cables, this heat generation becomes exponentially problematic. Traditional air-cooled cables have practical thickness limitations – cables must remain manageable for everyday users while maintaining safety standards.

This resistance-heat relationship creates a technological ceiling. Conventional charging cables can only handle so much current before becoming dangerously hot or impractically thick. Most standard Level 2 AC chargers deliver between 7-22 kW of power, while even DC fast chargers typically max out around 150-350 kW. These rates still mean considerable waiting times for drivers – typically 30 minutes or more for substantial charging sessions.

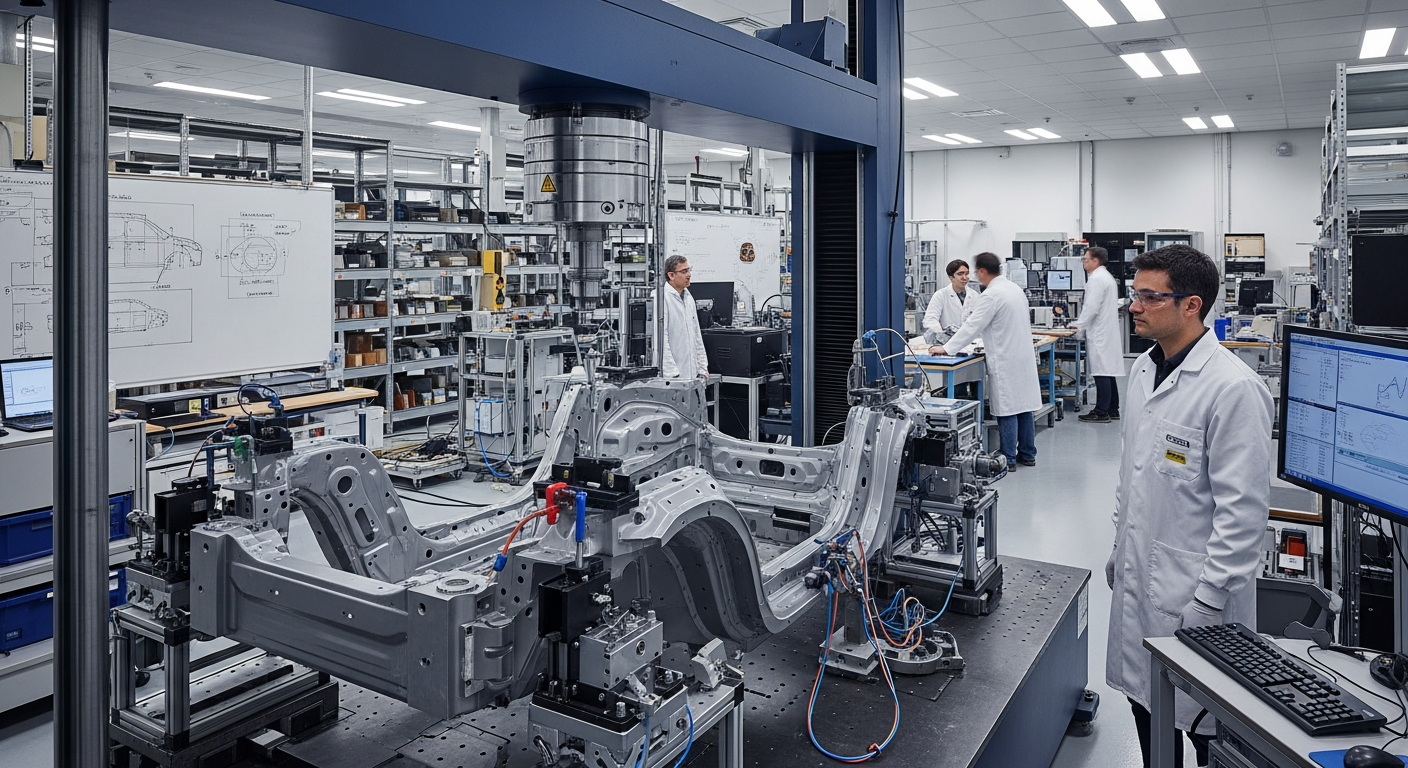

Engineering teams around the world recognized this bottleneck as a critical barrier to EV adoption. The solution required thinking beyond traditional cable design to fundamentally reconsider how we manage heat during high-power electrical transfer.

How Liquid Cooling Technology Works

Liquid-cooled charging cables represent an elegant engineering solution to the heat dissipation challenge. The fundamental concept involves integrating cooling channels directly alongside the electrical conductors within the charging cable. These channels carry specialized coolant fluids that continuously absorb and remove heat generated during charging.

The design typically features copper conductors surrounded by insulation, with coolant running through dedicated tubes that parallel the electrical pathways. The entire assembly is then wrapped in flexible, durable exterior materials suitable for daily handling. Cooling systems at the charging station circulate the coolant, maintaining optimal operating temperatures even at extreme power levels.

This cooling approach allows for significantly smaller cable diameters while handling much higher currents. A liquid-cooled cable rated for 500 kW might maintain roughly the same flexibility and handling characteristics as a traditional 150 kW cable. Advanced versions utilize dielectric cooling fluids that are non-conductive, eliminating safety concerns even if leaks occur.

Some cutting-edge systems are now implementing phase-change cooling, where the coolant transitions between liquid and gas states, dramatically increasing heat absorption capacity. This technology borrows concepts from high-performance computing cooling systems, where similar thermal management challenges exist.

Breaking the Megawatt Barrier

The most exciting development in liquid-cooled charging technology is its ability to surpass the megawatt threshold – a power level previously unimaginable for consumer vehicles. Several manufacturers have now demonstrated prototype systems capable of delivering 1 MW (1,000 kW) or more through cables that remain manageable for everyday use.

At these power levels, charging dynamics change fundamentally. A vehicle with a 100 kWh battery pack – common in many premium electric vehicles – could theoretically recharge from 10% to 80% in under 5 minutes. This approaches the refueling experience of conventional gasoline vehicles, potentially eliminating one of the most significant practical barriers to widespread electric vehicle adoption.

Commercial vehicles stand to benefit even more dramatically. Electric semi-trucks with battery packs exceeding 500 kWh could use megawatt charging to restore significant range during mandated driver rest periods. This capability is critical for long-haul transportation, where vehicle downtime directly impacts operational economics.

Industry researchers are already exploring the next frontier: multi-megawatt charging systems that could deliver 2-4 MW through further refinements in liquid cooling technology. These would primarily serve commercial applications initially but demonstrate how the technology continues to evolve rapidly.

Standardization Efforts and Market Implementation

For liquid-cooled charging to achieve mainstream adoption, standardization is essential. Various industry consortia are currently working to establish technical specifications that ensure interoperability between charging stations and vehicles from different manufacturers.

The Megawatt Charging System (MCS) represents the most advanced standardization effort, focusing specifically on high-power applications. This standard defines connector designs, communication protocols, and safety requirements for next-generation charging systems. The MCS connector incorporates eight power contacts plus additional signal pins within a connector housing specifically designed for liquid cooling integration.

Equally important are the standards governing the cooling systems themselves. These must address coolant specifications, operating temperature ranges, pressure limitations, and maintenance requirements. Creating robust, harmonized standards is crucial for widespread deployment across different markets and climate conditions.

Early commercial implementations of liquid-cooled charging are already appearing at select locations. These installations typically serve as pilot projects, allowing operators to gather real-world performance data while demonstrating the technology to consumers. Full commercial rollout faces challenges including high installation costs, electrical grid capacity limitations, and the need for expanded technical training for maintenance personnel.

Future Implications for Electric Mobility

The implications of liquid-cooled charging technology extend far beyond simple convenience. By effectively eliminating charging time as a practical concern, these systems could fundamentally alter how we think about vehicle range and usage patterns.

For passenger vehicles, multi-hundred kilowatt charging capabilities might mean rethinking battery sizing strategies. Manufacturers could potentially design vehicles with smaller, lighter battery packs that charge more frequently but extremely quickly. This approach would reduce vehicle weight, improve efficiency, lower manufacturing costs, and decrease resource consumption – all while maintaining practical usability.

For fleet operations, ultra-fast charging creates new possibilities for vehicle utilization. Taxis, delivery vehicles, and other high-utilization applications could operate continuously with minimal downtime, improving operational economics. This shift could accelerate fleet electrification in sectors where charging time constraints have been prohibitive.

The technology also creates new possibilities for charging infrastructure deployment. Highway rest areas could feature high-power charging plazas where vehicles charge in 5-10 minutes while drivers take brief breaks. Urban charging hubs might function more like traditional gas stations, with vehicles moving through quickly rather than occupying spaces for extended periods.

Perhaps most significantly, liquid-cooled charging demonstrates how innovation continues to accelerate throughout the electric vehicle ecosystem. What seemed impossible just five years ago is now being demonstrated in commercial installations, showing how rapidly limitations can be overcome through focused engineering and investment.

As these systems mature and costs decrease through scale, liquid-cooled charging technology will likely become the standard approach for all high-power charging applications. The days of anxiously waiting for your vehicle to charge may soon become a relic of the early electric vehicle era, replaced by an experience that feels familiar to anyone accustomed to traditional refueling – but powered by electricity rather than fossil fuels.