Hydrogen-Electric Powertrains: The Bridge Technology Reshaping Motorsport

The thunderous roar of internal combustion engines has defined motorsport for over a century, but beneath the surface, a quiet revolution is gaining momentum. Hydrogen-electric powertrains are emerging as a fascinating bridge technology that could transform racing while preserving the soul and spectacle fans cherish. Unlike pure battery-electric solutions that face range and recharging limitations, hydrogen fuel cells offer rapid refueling and extended operation—crucial factors in endurance racing. This hybrid approach combines hydrogen's energy density advantages with electric motors' instant torque delivery, creating a compelling package that's capturing the attention of racing teams, manufacturers, and governing bodies looking to balance performance with sustainability goals.

The Science Behind Hydrogen-Electric Propulsion

Hydrogen-electric powertrains represent a sophisticated merger of technologies that offer unique advantages for high-performance applications. At their core, these systems use hydrogen fuel cells to generate electricity through an electrochemical process rather than combustion. The hydrogen molecules interact with oxygen across a membrane, producing electricity with water vapor as the only emission. This electricity then powers electric motors that drive the wheels, delivering instantaneous torque and precise power control.

Modern racing-focused hydrogen fuel cells have achieved impressive power density, with some units exceeding 4 kW per kilogram—figures that continue to improve with racing development. These systems typically operate alongside modest battery packs that serve as power buffers, capturing regenerative braking energy and providing additional power during acceleration. The hydrogen itself is stored in carbon-fiber reinforced tanks at pressures up to 700 bar, ensuring sufficient range for extended racing applications while meeting stringent safety standards.

The modular nature of hydrogen-electric systems allows engineers to optimize weight distribution throughout the vehicle, potentially improving handling characteristics compared to traditional powertrains with fixed engine positions. This flexibility creates new opportunities for chassis design that would be impossible with conventional engines.

Racing Series Leading the Hydrogen Charge

The world of motorsport is gradually embracing hydrogen-electric technology across various disciplines. Le Mans, with its storied history of technological innovation, has proven particularly receptive. The Automobile Club de l’Ouest (ACO), which oversees the 24 Hours of Le Mans, has created a special hydrogen category set to debut in 2026, with demonstration vehicles already testing during race weekends. These prototypes use both direct hydrogen combustion and fuel cell approaches, offering fascinating comparative data for manufacturers.

In off-road racing, the Extreme H series is developing as a hydrogen-powered counterpart to Extreme E, tackling challenging terrain while showcasing the technology’s durability. Meanwhile, several Formula 1 teams are quietly investigating hydrogen applications through their advanced technology divisions, exploring potential integration into future power unit regulations beyond 2026.

The Mission H24 project has been particularly influential, running hydrogen prototypes in support races for major endurance events. Their latest vehicle delivers over 650 horsepower from a fuel cell stack weighing just 120 kilograms, demonstrating performance approaching that of conventional GT race cars. These real-world applications are crucial for development, as they subject hydrogen systems to the extreme conditions and competitive pressures that accelerate innovation.

Performance Characteristics and Racing Dynamics

Hydrogen-electric race cars exhibit driving dynamics distinctly different from both traditional combustion engines and battery-electric vehicles. Drivers report exceptional throttle response due to electric motors delivering 100% torque from zero RPM, allowing for precise power application when exiting corners. This characteristic has proven especially valuable in technical circuit sections where traditional engines might struggle with turbo lag or torque gaps.

The refueling process represents another significant difference, with hydrogen cars capable of replenishing energy stores in under five minutes—comparable to traditional pit stops and dramatically faster than battery charging. This operational advantage preserves the strategic elements of endurance racing that would be compromised by lengthy recharging periods.

The weight distribution of hydrogen-electric race cars tends toward a mid-centered balance, as the fuel cell stacks, modest battery systems, and electric motors can be positioned optimally throughout the chassis. Engineers have found this creates predictable handling characteristics that drivers can exploit confidently at the limit. The thermal management requirements, however, present unique challenges, as fuel cells must operate within specific temperature ranges for peak efficiency, adding complexity to cooling system design.

Sound profiles differ markedly from combustion engines but aren’t silent like battery electrics. Current hydrogen race prototypes produce a distinctive high-pitched whine from their air compressors and cooling systems, combined with the mechanical symphony of transmission components and tire noise—creating a futuristic auditory experience that preserves some of the sensory excitement fans and drivers value.

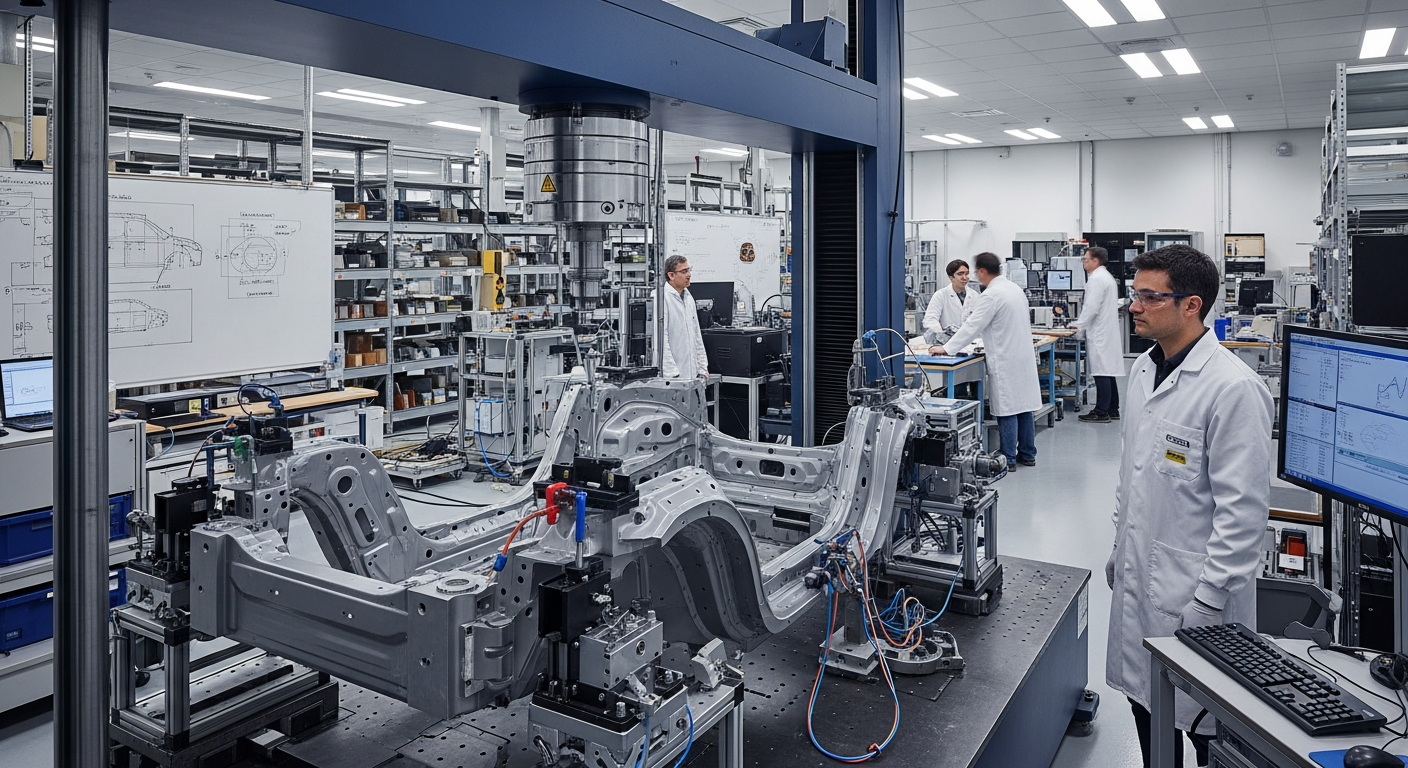

Manufacturing Challenges and Safety Protocols

Developing hydrogen-electric race cars presents substantial engineering challenges that teams are actively addressing. The fuel cell stacks themselves require specialized manufacturing capabilities, with platinum-coated membranes and precision assembly processes ensuring consistent performance under racing conditions. These components must withstand extreme vibration, g-forces, and temperature variations never encountered in stationary applications.

Safety protocols for hydrogen racing are necessarily rigorous and have evolved substantially in recent years. Modern hydrogen tanks incorporate multiple redundant safety systems, including impact-resistant outer shells, leak detection sensors, and pressure relief devices. Race vehicles undergo specialized crash testing to ensure hydrogen containment even in severe accidents. Track facilities are being modified with hydrogen-specific safety equipment, including specialized fire suppression systems and detection devices calibrated for hydrogen’s unique properties.

The manufacturing processes for racing components are gradually influencing production techniques for road-going hydrogen vehicles, creating a technology transfer pathway similar to what occurred with carbon fiber, aerodynamics, and electronic control systems in previous decades. Race teams are developing new rapid-diagnostic tools for fuel cell systems, allowing technicians to quickly identify and address performance issues between sessions—critical capabilities for both racing and future consumer applications.

Future Trajectory and Manufacturer Investment

Major automotive manufacturers are increasingly viewing motorsport as a proving ground for hydrogen-electric technology. Toyota, Hyundai, and BMW have all established dedicated hydrogen racing programs, using the extreme demands of competition to accelerate development cycles. These programs often operate in parallel with their production hydrogen vehicle divisions, sharing personnel and discoveries to maximize technological advancement.

The investment extends beyond vehicle development to infrastructure adaptation. Racing circuits are installing hydrogen refueling facilities that operate at the pressures and flow rates necessary for competition, creating knowledge that transfers directly to consumer infrastructure development. Each race weekend generates valuable data on real-world hydrogen logistics, storage requirements, and safety protocols under demanding conditions.

Regulatory bodies are carefully mapping out technical evolution to balance competition with development. The FIA has established a hydrogen working group that includes experts from aerospace, energy, and automotive fields to create comprehensive technical regulations. These frameworks include progressive efficiency targets that encourage continuous innovation while maintaining competitive balance between teams.

The true potential of hydrogen-electric racing lies in its ability to serve as a development accelerator. The compressed timelines and competitive pressures of motorsport historically drive rapid innovation—exactly what hydrogen technology needs to reach commercial viability. As these racing programs mature, they create a pipeline of specialized engineers and technicians with hydrogen expertise that will eventually filter into production vehicle programs, building the knowledge base necessary for broader adoption beyond the racetrack.