Automation Integration for Operational Efficiency

In today's dynamic business landscape, the integration of automation technologies has become a pivotal strategy for organizations aiming to enhance their operational efficiency. This approach moves beyond simple task mechanization, encompassing a comprehensive redesign of processes to leverage advanced robotics, artificial intelligence, and sophisticated software. By strategically implementing these tools, enterprises can achieve significant improvements across various functions, from manufacturing floors to complex global supply chains, ultimately fostering greater productivity and competitive advantage.

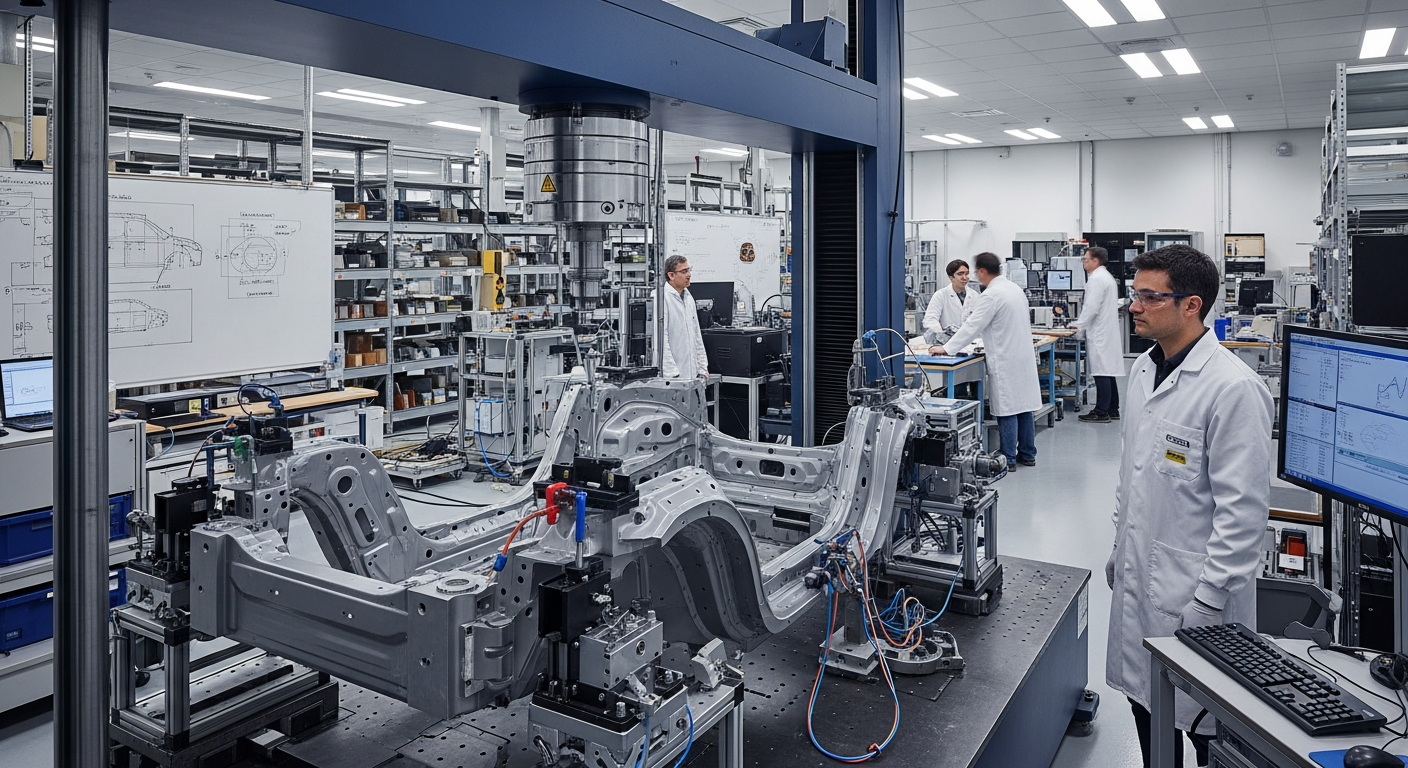

How Automation Enhances Manufacturing and Production?

Automation plays a transformative role in modern manufacturing and production environments. By deploying advanced robotic systems and intelligent software, enterprises can streamline repetitive tasks, improve precision, and increase output capacity. This integration leads to a reduction in human error, consistent product quality, and accelerated production cycles. Furthermore, automated systems can operate continuously, minimizing downtime and maximizing asset utilization, which is crucial for meeting the demands of global markets and maintaining an efficient production flow.

Streamlining Operations and Logistics Through Technology?

Operational and logistics processes are significantly optimized through the strategic application of technology and automation. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are revolutionizing warehouse management and internal material handling, improving speed and accuracy in picking, packing, and sorting. In logistics, advanced planning software, real-time tracking, and predictive analytics enhance route optimization, inventory management, and distribution networks. These technological advancements contribute to more responsive supply chains, reduced operational costs, and improved delivery times, supporting seamless commerce and enterprise-wide efficiency.

Strategic Development for Global Supply Chain Efficiency?

Developing a robust strategy for automation integration is critical for achieving efficiency across global supply chains. This involves evaluating current processes, identifying bottlenecks, and implementing innovative solutions that connect various stages of the supply chain, from sourcing and production to distribution and customer delivery. Cloud-based platforms and Internet of Things (IoT) devices facilitate real-time data exchange, enabling better coordination and decision-making across geographically dispersed operations. Such strategic development ensures resilience and adaptability, crucial for navigating the complexities of international trade and market fluctuations.

Workforce Evolution and Sustainable Automation?

The integration of automation also brings about an evolution in the workforce, shifting the focus from manual, repetitive tasks to roles that require oversight, maintenance, and strategic planning of automated systems. Companies investing in automation often prioritize upskilling and reskilling programs to equip their employees with the necessary technological competencies. This approach fosters a more engaged and highly skilled workforce. Moreover, sustainable automation practices consider the environmental impact, aiming for energy-efficient solutions and waste reduction, contributing to long-term enterprise sustainability and responsible development.

Leveraging Analytics for Market Distribution and Commerce?

Data analytics is a powerful tool in maximizing the impact of automation on market distribution and commerce. By collecting and analyzing data from automated systems, businesses can gain deep insights into customer behavior, market trends, and distribution channel performance. Predictive analytics can forecast demand more accurately, allowing for optimized inventory levels and reduced stockouts. This data-driven approach enables enterprises to refine their distribution strategies, personalize customer experiences, and make informed decisions that drive growth and enhance overall efficiency in competitive markets.

Automation integration involves various technologies, each with different cost implications depending on scope, complexity, and customization. Understanding these potential costs is essential for any enterprise considering such an investment. Prices are estimates and can fluctuate significantly based on provider, region, and specific project requirements. It is important to conduct thorough research and obtain detailed quotes tailored to your organization’s needs.

| Product/Service | Provider Category | Cost Estimation (USD) |

|---|---|---|

| Robotic Process Automation (RPA) Software | Software Vendors | $5,000 - $15,000 per bot/year |

| Industrial Robotics (e.g., Cobots) | Robotics Manufacturers | $25,000 - $100,000+ per robot |

| Warehouse Management Systems (WMS) | Enterprise Software Providers | $10,000 - $250,000+ (software & implementation) |

| Custom Automation Consulting | Specialized Consulting Firms | $150 - $400+ per hour |

| Automated Guided Vehicles (AGVs) | Automation System Integrators | $30,000 - $150,000+ per vehicle |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, the integration of automation is a multifaceted strategy that significantly enhances operational efficiency across manufacturing, operations, logistics, and global supply chains. By embracing technology, fostering workforce development, and leveraging data analytics, businesses can achieve substantial improvements in productivity, sustainability, and market responsiveness. This ongoing innovation positions enterprises to navigate complex challenges and capitalize on opportunities in an increasingly interconnected and competitive global economy.