Global Supply Chain Optimization Strategies

In an increasingly interconnected world, the efficiency and resilience of global supply chains are critical for businesses across all industrial sectors. Optimizing these complex networks involves a strategic approach to managing the flow of goods, information, and finances from raw material sourcing to final product delivery. Understanding the core principles and implementing effective strategies can significantly enhance operational performance, reduce costs, and strengthen a company's competitive position in the global market.

Global supply chain optimization represents a comprehensive effort to maximize value and minimize waste within the intricate web of activities that bring products and services to consumers worldwide. This process extends beyond mere cost-cutting, encompassing strategic decisions that impact every stage, from initial design and manufacturing to final distribution and customer service. Businesses operating in a globalized economy face constant pressure to adapt to market fluctuations, geopolitical shifts, and technological advancements, making a robust and agile supply chain an indispensable asset for sustained success. Effective optimization can lead to improved product quality, faster market entry, and enhanced customer satisfaction.

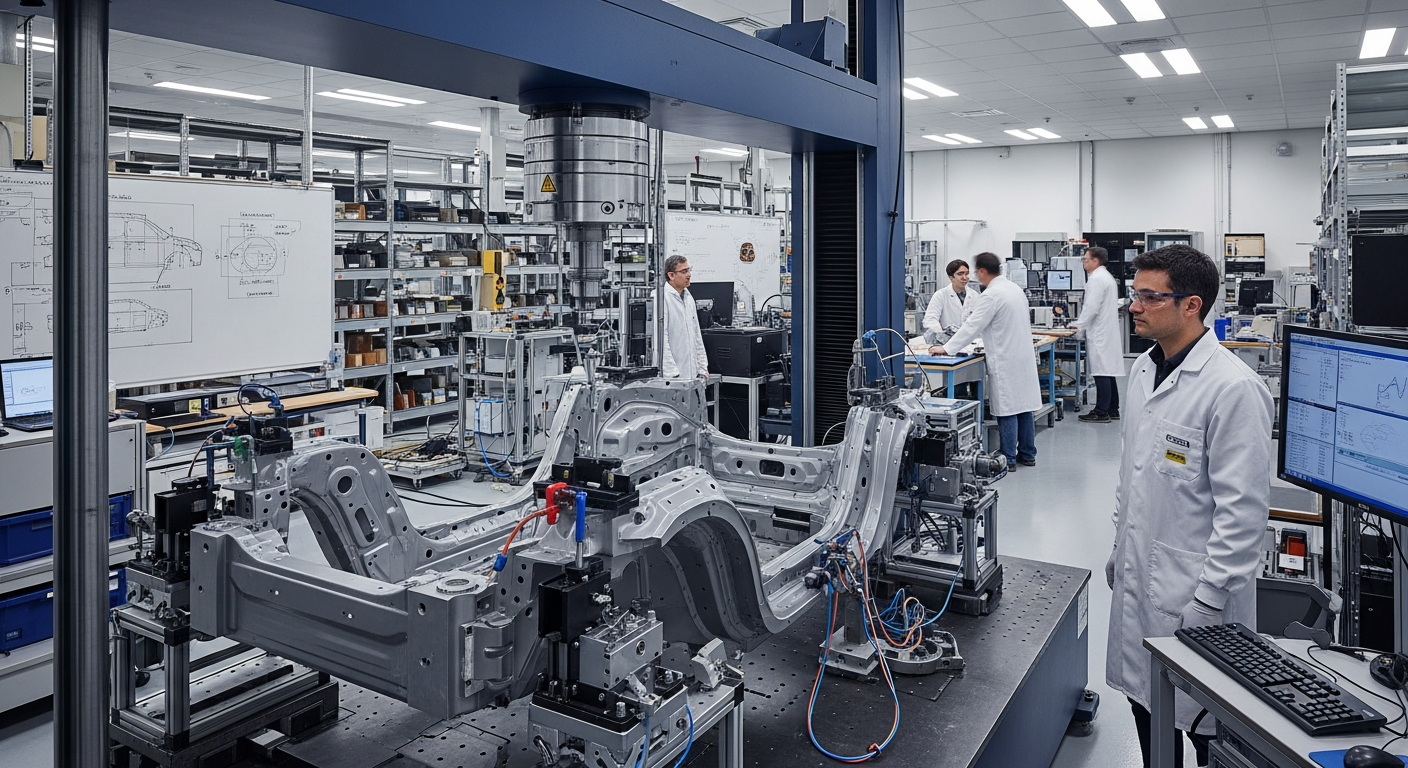

Enhancing Operations and Manufacturing Efficiency

Achieving peak operational efficiency in manufacturing is foundational to supply chain optimization. This involves streamlining production processes, minimizing lead times, and reducing waste through methodologies such as lean manufacturing. Companies focus on precise inventory management, ensuring that raw materials and components are available exactly when needed for production, thereby avoiding costly overstocking or disruptive shortages. Continuous analysis of production flows and capacity utilization helps identify bottlenecks and areas for improvement, contributing to a more agile and responsive manufacturing environment. By integrating data-driven insights, enterprises can make informed decisions that directly impact the overall efficiency of their global operations.

Strategic Logistics and Global Distribution Networks

Logistics management plays a pivotal role in linking various stages of the supply chain, ensuring the timely and cost-effective movement of goods across borders. Optimizing logistics involves careful planning of transportation routes, warehouse locations, and inventory levels to meet market demand efficiently. For global trade, this means navigating diverse regulatory landscapes, customs procedures, and transportation infrastructures. Developing robust distribution networks that can adapt to regional demands and unexpected disruptions is key. Businesses often leverage sophisticated network modeling tools to design and refine their distribution strategies, aiming to reduce transit times and associated costs while maintaining high service levels for customers in various markets.

Leveraging Technology and Automation for Supply Chain Management

Technology is a primary enabler of modern supply chain optimization. Advanced systems such as Enterprise Resource Planning (ERP), Supply Chain Management (SCM) software, and Warehouse Management Systems (WMS) provide integrated platforms for real-time data visibility and control. Automation, particularly through robotics in production and warehousing, significantly improves speed, accuracy, and consistency. Furthermore, emerging technologies like Artificial Intelligence (AI) and machine learning are being deployed for demand forecasting, predictive analytics, and risk management, allowing companies to anticipate market changes and mitigate potential disruptions more effectively. The Internet of Things (IoT) provides granular tracking of goods, enhancing transparency across the entire infrastructure.

Cultivating Innovation and Sustainable Growth Strategies

Innovation is not limited to product development; it extends to processes and strategies within the supply chain. Companies are continuously exploring new methods for sourcing, manufacturing, and delivering goods that are both efficient and sustainable. This includes adopting greener logistics practices, optimizing packaging, and exploring circular economy principles to reduce environmental impact. Strategic development involves fostering a culture of continuous improvement and adaptability, enabling the supply chain to evolve with changing market dynamics and consumer expectations. By prioritizing sustainable practices and embracing new ideas, businesses can achieve long-term growth and enhance their corporate reputation while contributing positively to global commerce.

Building a resilient global supply chain requires ongoing commitment to strategic planning, technological adoption, and operational excellence. It involves a holistic approach that integrates all aspects of business and industrial operations, from initial production to final market distribution. Through continuous adaptation and a focus on efficiency, companies can navigate the complexities of global trade, mitigate risks, and position themselves for sustained development and competitive advantage.